Application And Verification Of Thread Gauge

(1)Principle of gauge use(1) General rule.

In the daily inspection of thread, there are often disputes about the use of gauges. That is to say, when the thread is inspected with the new gauge and the old gauge, different inspection conclusions may appear.

(2) The standard stipulates that:

Using thread gauge (ring gauge and plug gauge) to inspect the thread of commercial fastener is the only measurement method that can determine whether the product is accepted or not.

When thread gauges and measuring instruments are used in the inspection, no fastener shall be rejected if the thread size is within the specified limits. It is decisive to check the qualification of thread with a thread gauge.

(3) Thread gauge inspection function.

Go is used to check the maximum physical dimension (i.e. active pitch diameter) of the thread.

(LO ring gauge) or no go gauge (HI plug gauge) is used to check the single pitch diameter of the thread.

Check with a smooth ring gauge or smooth plug gauge. It is also allowed to check the major diameter of the external thread and minor diameter of internal thread with an indicator gauge (micrometer or caliper).

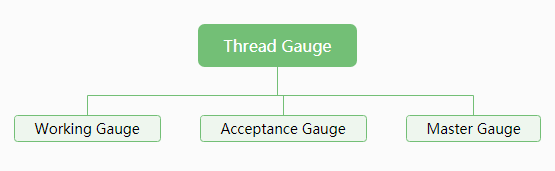

Gauge classification name and Application.

(1) Working gauge

The thread gauge used in production, manufacture, and inspection of fastener thread.

(2) Acceptance gauge

The thread gauge used by the inspection department or the user’s representative when accepting the thread of the fastener.

(3) Master Gauge

The thread gauge used by the inspection department or the user’s representative when accepting the thread of the fastener. Check whether the working thread gauge is qualified in manufacturing and inspection.

The qualification of the thread ring gauge is verified by the thread checking gauge (qualitative judgment).

Thread plug gauge with thread three-needle inspection measurement is qualified (quantitative judgment).

Requirements for gauge use

(1) The design tolerance position of thread gauge is within the limit dimension of product thread. In order to solve the dispute caused by the difference of the actual limit value (new and old wear) of the new and old gauges in practical use.

(2) In the American Standard ANSI B1.2:2007 and international ISO1502 standard, it is also proposed that the screw thread gauge is divided into two kinds of gauges: Working Gauge and acceptance gauge (American scalar gauge x positive and w negative deviation).

(3) Working gauge and acceptance gauge.

|

Classification |

Scope of application |

Gauge condition |

|

Working gauge |

Thread inspection gauge for production process | Use a new or less worn through thread gauge |

| Use old or worn end thread gauge | ||

|

Acceptance gauge |

The thread gauge used by the inspection department or the user’s representative when accepting the thread of the fastener. | Use old or worn through thread gauge |

| Use a new or less worn end thread gauge |

Thread inspection gauge for fastener products

(1) Thread inspection gauge is different. According to GB, ISO, DIN, ANSI, BS standards, the inspection summary of thread gauge is as follows:

|

Thread |

metric system | American system | British system |

|

External Thread |

6g | 2A | M |

|

Internal Thread |

6H | 2B | N |

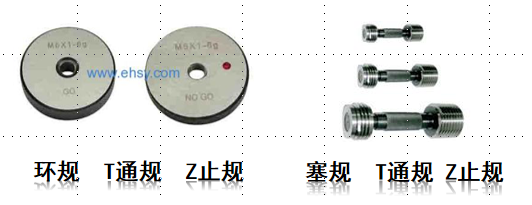

(2) Go/No go gauge

In the thread inspection of commercial fasteners, the gauges used are ring gauge (fixed and adjustable), plug gauge, and micrometer, which are used for qualitative judgment of qualification.

Ring gauge Plug gauge

Stationary type Adjustable

Function and use of metric thread gauge

|

Gauge |

Code |

Function |

Instructions |

|

|

Nuts |

Through end plug gauge |

T |

Check the virtual pitch diameter and major diameter of internal thread | Free screwing in |

| Not-go-end plug gauge |

Z |

Check single pitch diameter of internal thread | Stop at 2 threads | |

|

Bolts |

Through end ring gauge |

T |

Check the virtual pitch diameter and minor diameter of internal thread | Free screwing in |

| Not-go-end ring gauge |

Z |

Check single pitch diameter of internal thread | Stop at 2 threads | |

|

Master plug gauge

|

Master through end plug gauge -Through |

TT |

Check the virtual pitch diameter of the new thread ring gauge | Free screwing in |

| Master through end plug gauge - Not-go-end |

TZ |

Check the single pitch diameter of the new thread ring gauge | Screw in≤ 1 thread | |

| Master through end plug gauge - Loss |

TS |

Check the single pitch diameter of the thread ring gauge used | Screw in≤ 1 thread | |

| Master not-go-end plug gauge - Through |

ZT |

Check the virtual pitch diameter of the new not-go-end ring gauge | Free screwing in | |

| Master not-go-end plug gauge - Not-go-end |

ZZ |

Check the single pitch diameter of the new not-go-end ring gauge | Screw in≤ 1 thread | |

| Master not-go-end plug gauge - Loss |

ZS |

Check the single pitch diameter of the not-go-end ring gauge used | Screw in≤ 1 thread | |

Function and use of American thread gauge

|

Gauge |

Code |

Function |

Instructions |

|

|

Nuts |

Through end plug gauge |

GO |

Check the virtual pitch diameter and major diameter of internal thread | Free screwing in |

| Not-go-end plug gauge |

NO GO |

Check single pitch diameter of internal thread | Stop at3 threads | |

|

Bolts |

Through end ring gauge or adjustable type |

GO |

Check the virtual pitch diameter and minor diameter of internal thread | Free screwing in |

| Not-go-end ring gauge or adjustable type |

NO GO |

Check single pitch diameter of internal thread | Stop a 3 threads | |

|

Master ring gauge

|

Master plug gauge |

GO and NO GO |

Check the action pitch diameter of adjustable ring gauge | Check full thread and thread section |

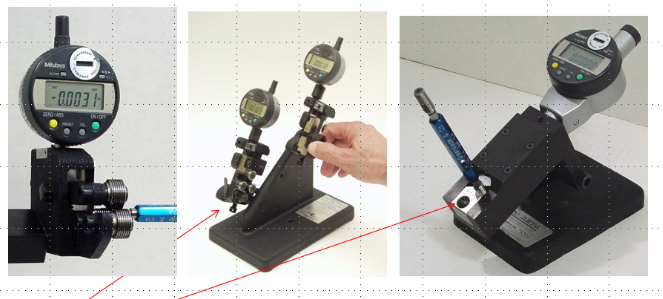

Indicator gauge is a developing trend in foreign countries. It is a fast tool for thread qualification inspection. On the one hand, it can make a qualitative judgment, on the other hand, it can measure the size of parameters.

Thread indicator gauge

120°Three-wheel single-center diameter measuring head

Micrometer method for measuring the major diameter

Characteristic:

• Detection of single pitch diameter

• It is impossible to detect the middle diameter of action

• The internal thread cannot be detected

• Low precision, used for low precision thread measurement

Verification of thread ring gauge

(1) There are two calibration methods for thread ring gauge

It is a qualitative judgment to calibrate the working thread ring gauge with the thread checking plug gauge.

It is a quantitative judgment to use length measuring instrument, wangei tool microscope, and its accessories (such as internal measuring hook, measuring ball, proofing ring, etc.).

(2) Methods and requirements of thread ring gauge calibration

All the thread ring gauges should be clean between the threads, and no oil and impurities are allowed to attach to the threads.

All thread ring gauge and thread shall be in good condition, and no scar or defect is allowed.

Take the go gauge corresponding to the threaded ring gauge, and screw the go gauge end of the plug gauge into the go gauge (ring gauge) smoothly, but not the non-stop gauge (gauge ring).

The check gauge end of the check plug gauge corresponding to the threaded ring gauge cannot be screwed into the go gauge (ring gauge) or the non-stop gauge (ring gauge). When checking and checking the thread ring gauge, it is allowed to refer to the relevant standards for the number of teeth that the check gauge can enter the ring gauge.

After proofreading, put the calibration equipment back in place to avoid damage.

The plug gauge can not be operated vigorously when checking the thread angle and pitch.

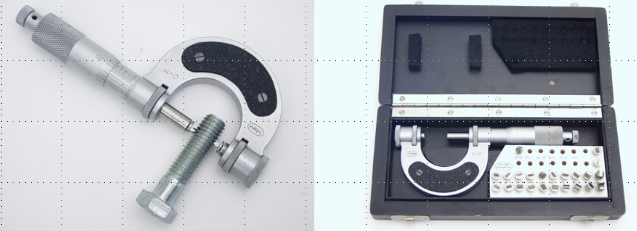

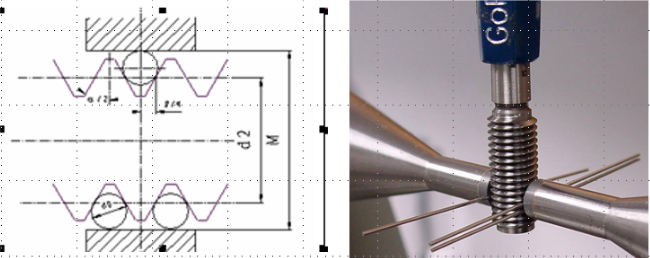

Three-pin measurement of thread plug gauge

(1) Pitch diameter effectiveness of thread plug gauge.

The three-needle method can be used for testing. According to the P (pitch) and thread angle (α) of the thread gauge, the best needle diameter is selected to determine the

qualification of the screw plug gauge.

(2) The best formula of three needles and measurement.

Optimum three needles diameter

|

thread angle α° |

Simplified calculation formula |

Application |

|

60° |

d0=0.577P |

Metric thread/American thread |

|

55° |

d0=0.564P |

British thread |

Calculation formula of three needle measurement

|

Thread |

Calculation formula |

|

60°Metric thread/American thread |

d2=M-3d+0.866P |

|

55°British thread |

d2=M-3.1657d+0.9605P |

Measurement procedure

Step 1: Select three needles according to the best formula according to the pitch

Step 2: Select the appropriate three needles

Step 3: Calculate the value of an according to the formula

Step 4: Compare the measured and calculated values with the standard parameters and draw a conclusion.

7. Use and maintenance of the gauge

•The measuring surface of gauge shall be free from rust and contamination;

•The connection between gauge and handle should be firm;

•The hardness is 58 HRC~65 HRC;

•The tolerance dimension of gauge meets the standard requirements;

•The roughness of the gauge is 0.32μm;

•Carry out weekly inspection according to the use condition

•The plug gauge should be inspected within 4-6 months after being used by factory operators;

•The ring gauge can be used for 20 days to 1 month in the factory and should be checked.

•Establish the use right account of gauge;

•It should be divided into a working gauge and an acceptance gauge.

Post time: Dec-04-2020